Copyright © Guangdong Foanxin Intelligent Manufacturing Technology Co., Ltd. All Rights Reserved. Site Map

- +86-18824806555

- faxzzy2424@126.com

- Floor 13, Tower A, Building 3, No. 311, Sanshui Avenue, Yundonghai Street, Sanshui District, Foshan City

Wire diameter | Gold wire: 15 ~ 75μm |

Aluminum wire: 18 ~ 100μm | |

Platinum wire: 18um ~ 25um | |

Silver wire: 18 ~ 50um | |

Gold ribbon: 50um×12.5um ~ 300um×25.4um | |

Device height | 31mm or 51mm (19mm length splitter) |

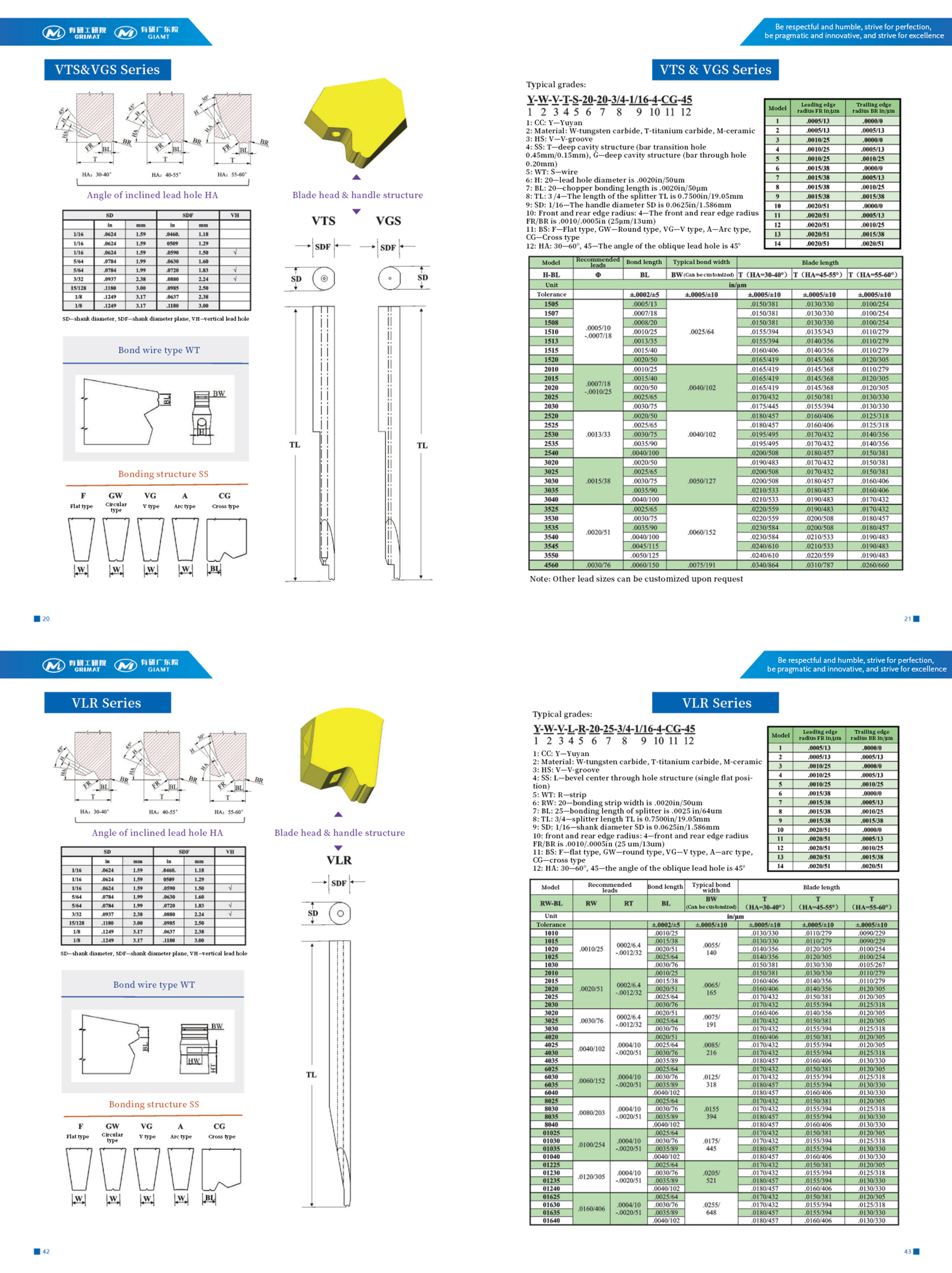

Type of riving knife | Φ1/16 19mm, 21mm, 25mm wedge welding splitter |

Φ1/16 16mm, 19mm ball welding splitter | |

Welding pressure | 1 ~ 250g, 1g subdivision adjustable |

Ultrasonic power | 0 ~ 5W, 5mW subdivision adjustable |

Bonding time | 0 ~ 1 second, 1 millisecond subdivision adjustable |

Locking method | Fully electric control, no compressed air required |

Welding head Z-axis travel | 18mm |

Welding head horizontal movement range | 15mm×15mm |

Wire clamp wire feeding travel | Max. 800um |

Wire feeding method | 90° (deep cavity) or 45° |

Operating table | Liftable height: 18mm |

Workbench area: 270mm×250mm | |

Wire feeding device | 1/2″ or 2″ spool, optional |

Human-machine interface | 7-inch LCD touch screen with a resolution of 1024*600 and multiple sets of buttons |

Working hot table | 3″ standard hot workbench, customizable |